Indian tooling industry catches momentum

April 8, 2022 11:35 am

Rising focus on industrial automation across the world is driving the Die and Casting industry.

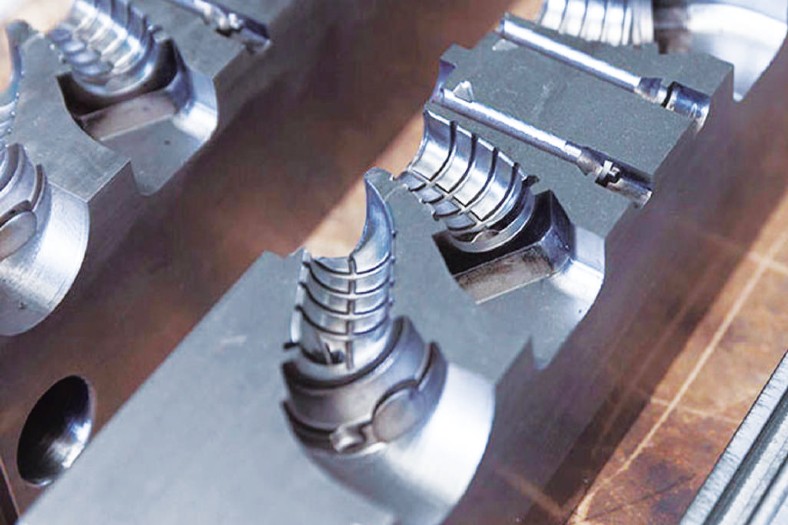

The growth of the die and mould market is driven by an increase in demand for more complex products, which require more sophisticated dies and moulds to manufacture them. In order to address the present challenges in the Indian tooling industry, the need of an ecosystem to develop it to become globally competitive is desirable. Using Industrial Robots for applications like milling, tape-laying and laser cutting is emerging as an area for growing interest.

The market dynamics indicate the global die and mould market growth at a 4.5 percent CAGR from 2021 to 2028. The automotive industry is the largest end-user of dies and moulds, accounting for over 40 percent of the total demand in 2018, according to Industry Growth Insight. The automotive industry is expected to continue its dominance in the coming years, with an estimated share of 45 percent by 2028. The demand for dies and moulds in other industries such as household appliance manufacturing and IT industry are also projected to grow at a CAGR of 5 percent. The growth of the market is getting influenced by increasing demand for new products in various industries. A major focus of the CAD/ CAM industry, currently, is on bridging the gap between subtractive and additive manufacturing.

Die and Mould automated technologies

Providing insight into ongoing epidemics still posing challenges, D M Sheregar, President, TAGMA India said, “Indian manufacturers are taking a variety of approaches to radically transform their businesses and find new ways to differentiate themselves. Companies are continually looking for technologies that can help them achieve accuracy and reduce cycle time.”

In view of the emerging shift seen in product manufacturing in India, Die and Mould automated technologies are gaining momentum and growing leaps and bounds. However, geographical barriers existing in view of changing scenarios have provided impetus to more automation. According to Ajoy Masand, Asst. VP Sales, Shree Rapid Technologies, “Surging trends indicate high growth due to increase in volume aiding development of the Die and Mould industry. Furthermore, technological advancements which are not being able to bring in manufacturing high precision products is one of the challenges faced by the industry.”

Increase in automation in the die casting industry has seen a surge in productivity. The die casting market has attracted the automotive industry, which is looking for highly durable die cast parts. Industrial machinery and piping manufacturers are increasingly employing die casting, since the past few years.

Automotive segment

The dies & mould segment is anticipated to dominate the market in the coming years, owing to its growing adoption in manufacturing of various automotive parts such as engines, clutch housings, gearbox housings, cylinder barrels, steering components, and many others. The rising focus on industrial automation across the world is driving the miniature parts zinc die casting market growth. The automotive industry offers significant growth opportunities for the global miniature parts zinc die casting market. The miniature parts zinc die casting market will be dominated by North America. The market is estimated to grow by USD 1.73 bn from 2021 to 2026.

The automotive sector is undergoing major reforms towards processing capabilities and automation. This promoted software processing capabilities combined with finesse in manufacturing high quality machinery. These all are catering to increasing customers demand for high end automotive vehicles remarks Ajoy.

Automotive segment will contribute to the largest share of the market. Zinc is the most popularly used metal for casting procedures in the automotive industry. Casting procedures produce lightweight, easily manoeuvrable, and affordable accessories. The rising production of automobiles, including four-wheelers and two-wheelers, will lead to significant growth in the demand for metal cast parts, which is driving the growth of the automotive segment

Rapid and Moulding prototyping technology

Rapid prototyping is used to cast silicone rubber mould, which are used to reproduce a small amount of plastic parts, which is very suitable for trial production of products. The use of aluminium to make injection moulds can shorten the injection cycle by 25-30 percent, greatly reduce the weight of the mould, and reduce the grinding and polishing time by half.

Combining rapid prototyping technology and rapid tooling technology in mould manufacturing, that is, using rapid prototyping technology to make prototypes of product parts, and then quickly manufacturing moulds based on the prototype. The cost of applying this technology from mould design to manufacturing is only 1/3 of the traditional method. Design changes on a product, for smaller batches, which require faster turnaround time on new dies or moulds, can be made quickly with less tooling costs involved than those required for large batches of products with long lead times between design changes on a product.

Future strategy

There is an apparent shift in the inclining trend for manufacturing industries from China to India. Ajoy sees it as a remarkable change, since politically influencing factors are causing a shift in business strategies by American and European companies in favour of India.

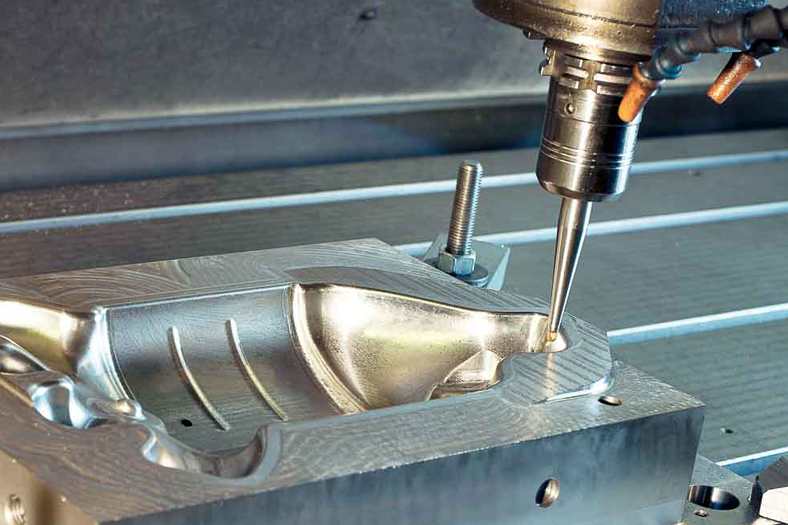

Multiaxis machining is defined by the motion of the cutting machine. In the traditional mould machining industry, it is common to use 3-axis machines such as vertical machining centres and double-column machining centres to cut metal. With the advancement of machining technology and mould requirements, some pros and cons have been identified in mould manufacturing. A 5-axis machine inherently has better reach than a 3-axis machine, which allows them to use shorter cutting tools. Shorter tools offer less vibration and deflection at high speeds.

With 5-axis, 3D shapes are not limited by fixturing or tool length. Its extra axes allow the tool and workpiece to move along new arcs and to orient themselves at almost any angle – and do so as the cutting tool is engaged with the material. Geometries that would have been impossible with 3-axis machining are simple with 5-axis. In the tooling industry, close to 90 percent of the Entrepreneurs/ Managers spend about 70-80 percent of the time in the day-to-day operations (Tactical) and less than 15- 20 percent of the time in strategic thinking is the opinion of Narendra Brahmankar, IRCA registered QMS Principal Auditor Trainer, Business Coach, and Consultant. Those who spend at least 10-15 percent of their time in cultivating the habit of strategic thinking within an organisation can improve operational efficiency & resource optimisation by a minimum of 25-30 percent.

Moving ahead

Indian manufacturers are taking a variety of approaches to radically transform their businesses and find new ways to differentiate themselves.

Companies are continually looking for technologies that can help them achieve accuracy and reduce cycle time. CAD/CAM dye manufacturing software solutions to meet the demands of industry in this field. Tool & Die manufacturers seek shorter cycle times and precision finishes for productivity and profit.

Certainly, the needs of the automobile and aerospace industries are constantly increasing, and high-speed 5-axis machining centres will play an increasingly important role in manufacturing. Post-pandemic geographical shift in manufacturing is evident due to restricted movement of goods and people. The future will be a new era of industrial competition of high speed and 5-axis machining. The Tool & Gauge Manufacturers Association of India platform for the die mould industry is scheduled to take place from April 27 – 30, 2022. Looking at the prevailing positive sentiment of the industry after the challenging two years, the show, which will be held after a gap of four years, is likely to get a good response from various industry verticals. D. Shanmugasundaram, Vice President, TAGMA India said, “The die mould India exhibition is the only dedicated event for tool and die makers which makes it unique and attracts visitors from diverse industries. In this edition, we are inviting delegates from 50 plus OEMs and the public sector, 10 plus user industry associations to explore business opportunities for tool makers. On behalf of TAGMA India, I invite industry professionals to visit the show and witness some of the latest developments in the industry.”

The players providing solutions to the industry are all geared up to cater to its specific requirements. Finally, there has been an increased interest from investors into this industry due to its high profitability. D M Sheregar, President, TAGMA India says, “The 2022 edition of Die Mould India is going to highlight the latest development in the field of tooling as companies are gearing up to showcase smart manufacturing solutions, newer tool geometries, the latest CNC machines, additive manufacturing solutions, integrated automation solutions, among others.” With over 300 exhibitors showcasing their technologies and solutions, we expect this edition to be a grand success. Die Mould India is a ‘must participate exhibition’ opportunity for all businesses related to the tooling Industry. Conclusively, the die and mould market is driven by the need to replace old Dies and the increasing demand for new products in various industries with new technologies gripping the market.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.