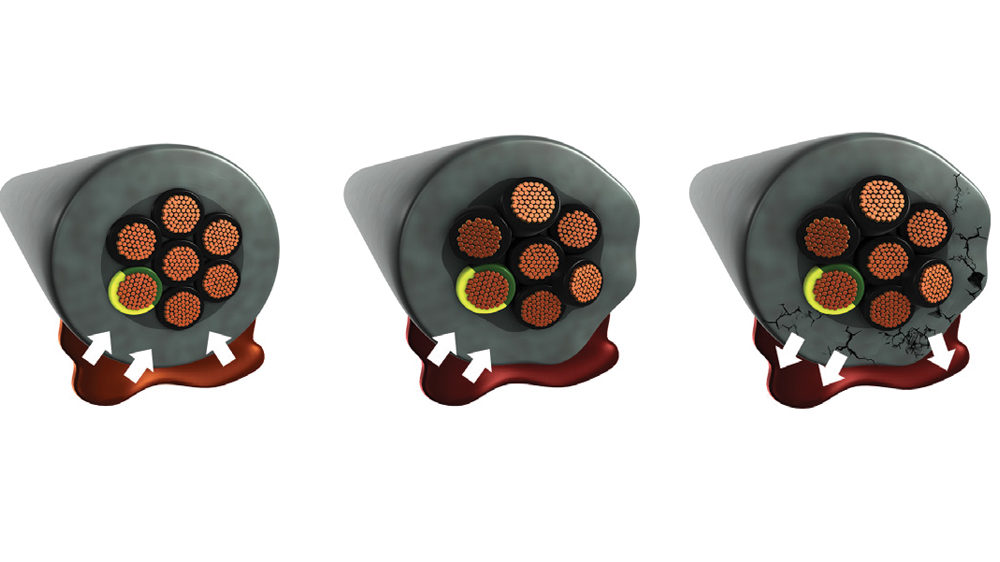

Visually diagnosing oil exposure problems

December 11, 2017 11:12 am

Cracking – Caused during exposure of the PVC to oil or other chemicals due the complete removal of plasticizers, resulting in hardening and eventual cracking of the insulation and jacket.

Melting – Caused during exposure of the PVC to oil or other chemicals due to the absorption and combination with the plasticizer, resulting in softening and the high elasticity noted in the compound.

Swelling – Caused during exposure of the PVC to oil or other chemicals due to migration of the oils into the plasticizer, resulting in noticeable increases in insulation and jacket diameter.

Discoloring – Caused during the exposure of the PVC to oil or other chemicals due to the diffusion of the plasticizers along with colorant from the insulation and jacket.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.