Injection moulding: Finding its rightful place in manufacturing

April 1, 2020 6:45 pm

Injection moulding is carving a niche for itself in manufacturing and is being increasingly seen as a modern, cost-effective technique for manufacturing plastics in bulk. We take a look at this important process and analyse how it is set to impact manufacturing in coming years.

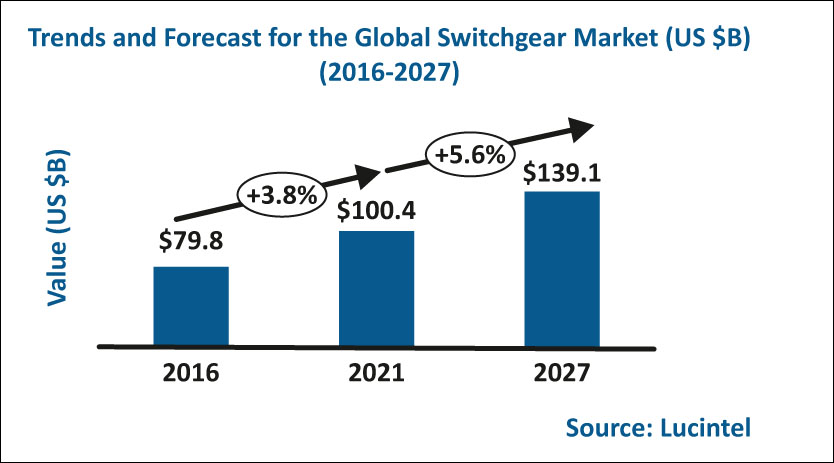

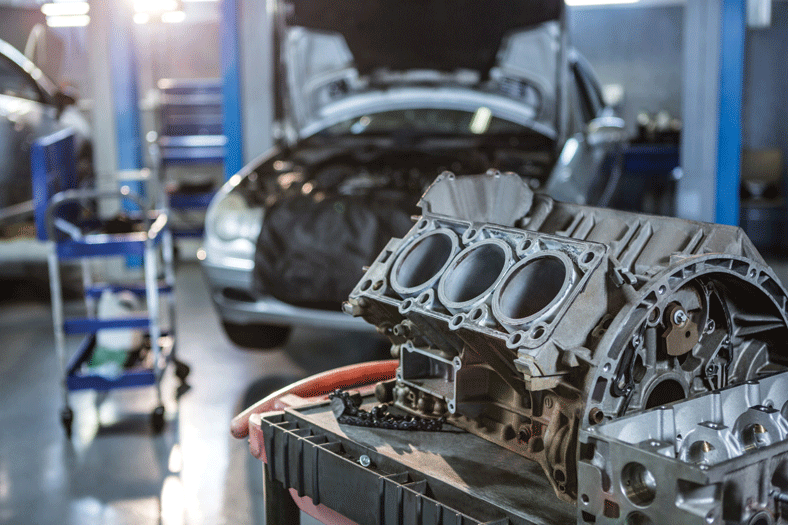

Injection moulding as an industrial manufacturing process is growing in its applications and significance. From automotive to construction to pharmaceuticals, it is used in different industries as a more economical means of mass production to meet the rapidly rising market demand of plastic gearing in various applications.

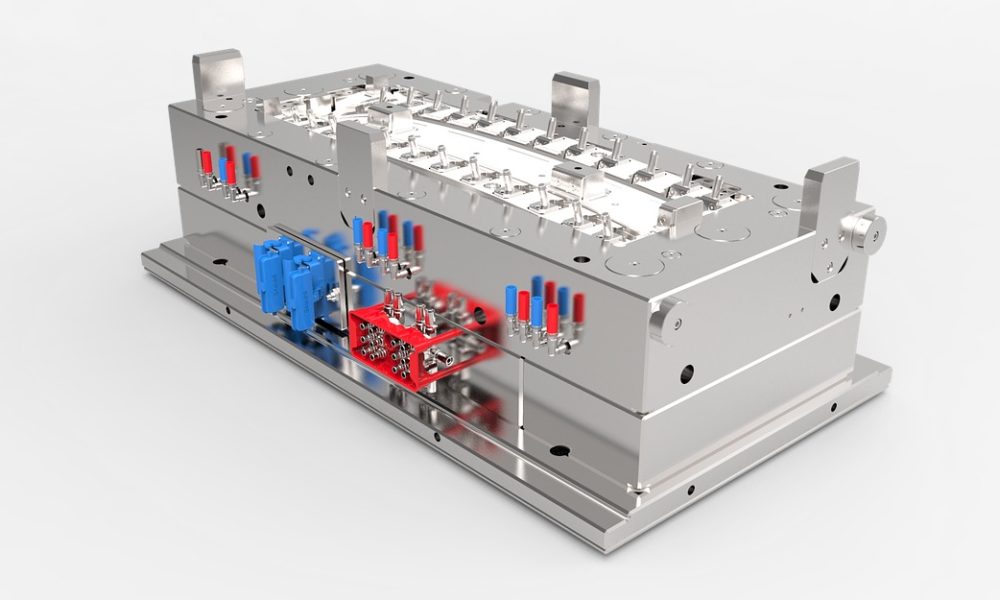

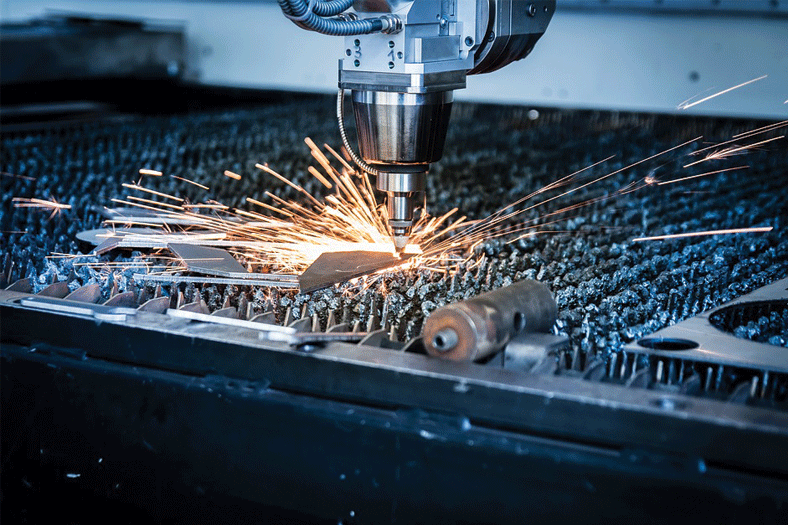

The injection moulding machine market is reported to grow from $17.1 billion in 2018 to $22.1 billion by 2027. According to Ninad Deshpande, Head – Marketing & Corporate Communication, B&R Industrial Automation, injection moulding is the process to manufacture parts by injecting molten material into a mould. Usually, thermoplastics are most commonly used for this process; thus, its most common applications are for the plastics and automotive industry. Use of such plastic parts is on the rise, making injection moulding a modern manufacturing technique for manufacturing plastic products. This is a relatively a cost-effective method of manufacturing large quantities of the same product.

Manufacturing of plastic gears

Plastic gears can be produced by hobbing or shaping, likewise to metal gears or alternatively by injection moulding. Gears have been in use for more than 3,000 years and are commonly utilised in power and motion transmission under different loads and speeds. Due to the fiscal and practical advantages, the demand of using plastics in the gearing sector has significantly increased and will undoubtedly continue in the future. In comparison with metal gears, plastic gears have several advantages such as light weight, noiseless running, resistance to corrosion, lower coefficients of friction, and ability to run under zero lubricated conditions.

Challenges in injection moulding

Until recently, developing part and tooling designs for injection moulding manufacturing required an iterative prototyping process to eliminate potential defects through trial and error. While this approach enables manufacturers to resolve manufacturability and tooling issues that can lead to defects such as air traps, voids, poorly placed parting lines, shrinkage, warpage, surface blemishes, structural weaknesses and large part deformation, it also adds time and cost to the process.

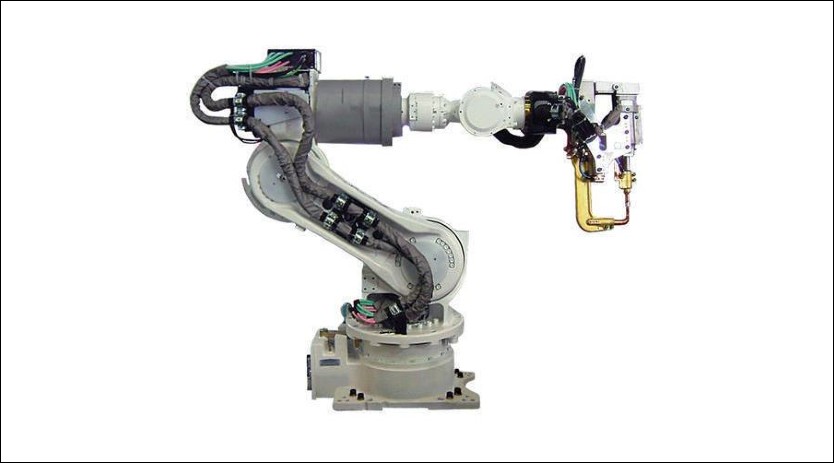

Deshpande added, “Maintaining and regulating extruder temperature for heating the substances is of prime importance. Many manufacturers use separate temperature controllers for regulating the temperature. With B&R, machine builders do not need to worry about using separate controllers for temperature control. Our mapp Technology provides innovative mechatronic solutions, enabling optimised closed-loop control of temperature processes. B&R is a preferred automation vendor and is proud of the fact that we are working with market leaders, from not only injection moulding manufacturers but also entire plastic industry manufacturers.” What’s really needed to streamline injection-moulded component and tooling development is the ability to perform the trial-and-error-driven prototyping process in an accurate, virtual environment.

Need for eco-friendly manufacturing of plastic injection moulds

Not all parts manufactured in the injection moulding process are good products. Many products could be rejected on the grounds of quality. However, reusing these waste products again for the purpose of manufacturing of new parts could enable reducing or even eliminating waste generated out of rejections. Deshpande shares, “One of our customers has effectively put into use this technique and has saved raw materials and managed to reduce waste.” Reducing injection moulding cycle times by opening moulds and ejecting high-quality parts in as short a time as possible is critically important. With the most advanced set of capabilities, plastic injection moulding simulation helps injection mould specialists achieve the optimal balance between fast cycle times and high-quality production. This supports the design and simulation of injection-mould cooling line layouts, the development of conformal cooling channel systems, the exploration of different types of materials and the optimisation of processing parameters to reduce or eliminate moulded-part warpage.

The future demand for injection moulds

Additive manufacturing has been around for quite some time; however, it has grown in prominence in recent years. Using 3D printing techniques reduces waste as well as provides effective utilisation of raw materials. Nonetheless, as Deshpande explained, “Today, we do not see 3D printing affecting the demand of injection moulding machines owing to several factors such as costs involved, design and financial constraints, technology complexity and capability. However, unfortunately, we would be unable to comment on the long-term future.”

New kinds of software that aid plastic injection moulding too enable designers to simulate the mould-filling stage, not so much for the purpose of developing actual tooling, but for understanding whether design modifications prior to mould development will speed tooling design, accelerate production and shorten time-to-market. To sum up, new innovations in this space will continue to complement the injection moulding process and help it develop into an important, pervasive manufacturing process that helps manufacturers reduce costs while improving moulding quality.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.