Addictive manufacturing: Facelift for Indian aerospace industry

July 12, 2018 6:07 pm

India has entered the rat race of manufacturing aerospace components with a bang. India has not only created a mammoth air support fleet on their own but are now exporting the resources and expertise to other countries.

Prime Minister Narendra Modi’s ‘Make in India’ has sprung a new hope for the Indian manufacturing sector. Though, in the past few decades’, Indian automotive sector has become one of India’s manufacturing giants,the aerospace sector is also witnessing a good policy move by the Indian Government.

Government organizations such as Hindustan Aerospace Limited (HAL) and Defence Research and Development Organization (DRDO) in collaboration with Russian Intel have successfully entered the turf, coming on par with aerospace giants such as Russia, USA and France to name a few. There are 5 major driving factors for the growth of Indian aerospace sector, viz. framework, government policies, infrastructure, competing industries and manpower. India, being a huge pool of abled workforce and skilled engineers, in alignment with the government policies had funding for development, which then showcased a massive uprising of aerospace research as a whole.

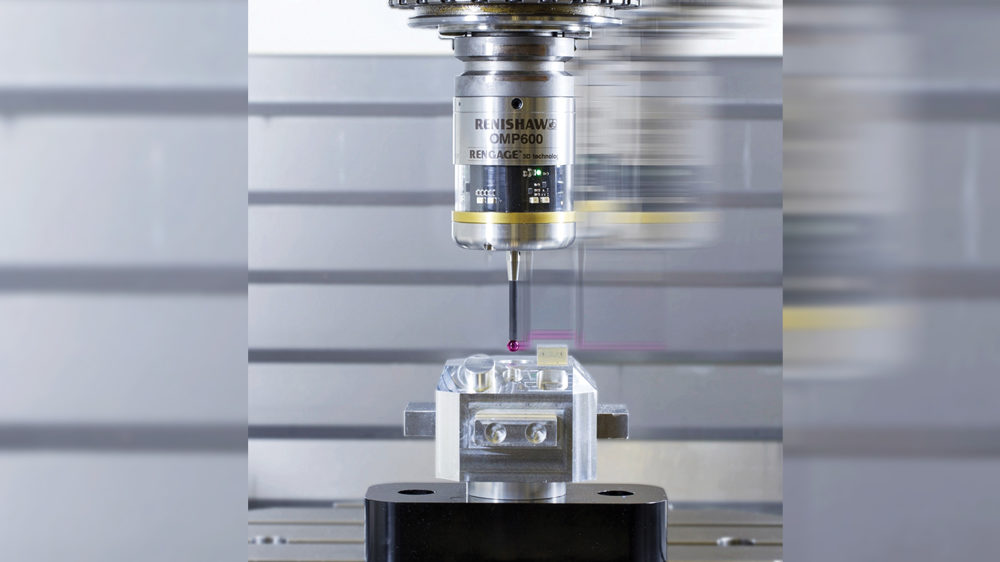

All this wouldn’t have been possible without the passionate involvement of the uncountable OEM and parts manufacturer across the country which provided the necessary components. Machine and tools manufacturers play a vital role in providing the tech needed to ease the process and increase potential. To compete with other nations, India needs to scale up and generate more focused architecture for aerospace manufacturing. Industries involving manufacturing units, part providers and die and mould industries should be dedicated to provide the resources necessary to felicitate the Indian industrial demand.

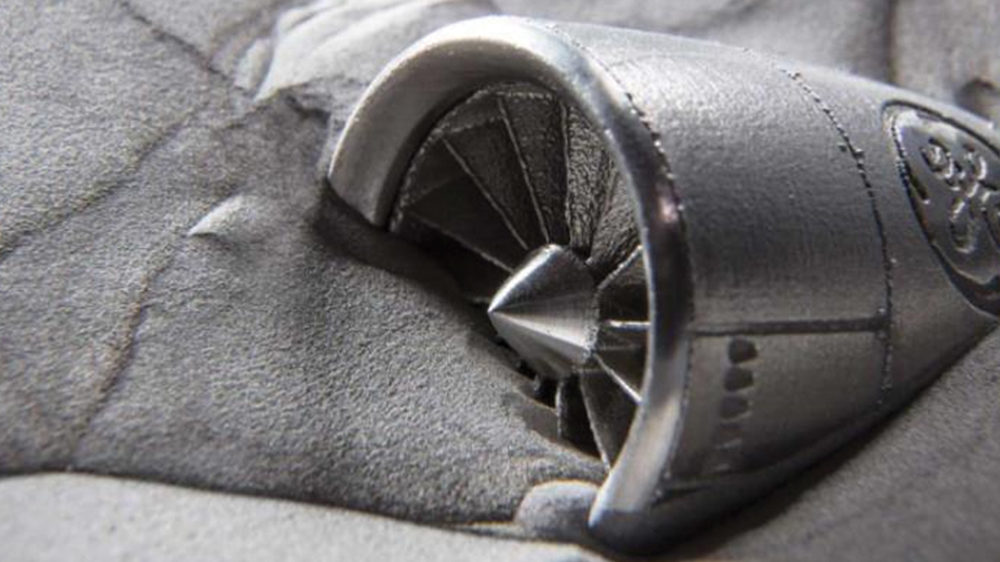

In this era of rapid technological development and never ending need for manufactured products, aerospace sector manifests a unique proposition where high value (accurate and optimized) parts with lesser numbers have to be produced. Here is where the trump card of additive manufacturing comes into play. Additive manufacturing is the missing link to leapfrog into the future of developing and producing critical components on demand. Companies such as GE, Moog Aerospace, and MTU Aero Engines are working hard to incorporate additive manufacturing into their current operation activities. Additive manufacturing has it perks where complexity isn’t a barrier and not much of tooling is required; hence, an advantage to test changes in component topology rapidly rather than simulating them virtually.

Inclusion of additive manufacturing in current Indian aerospace manufacturing market would be a boon without question. Encouraging conventional manufacturers and industrialists to get introduced and eventually adapt this technology can help reap the benefits of future aerospace and automotive builds. This will not only take the Indian manufacturing and tooling industry to the pinnacle of technological advancements but also boost Indian economy and thus, leading to social harmony.

For more details, visit www.objectify.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.