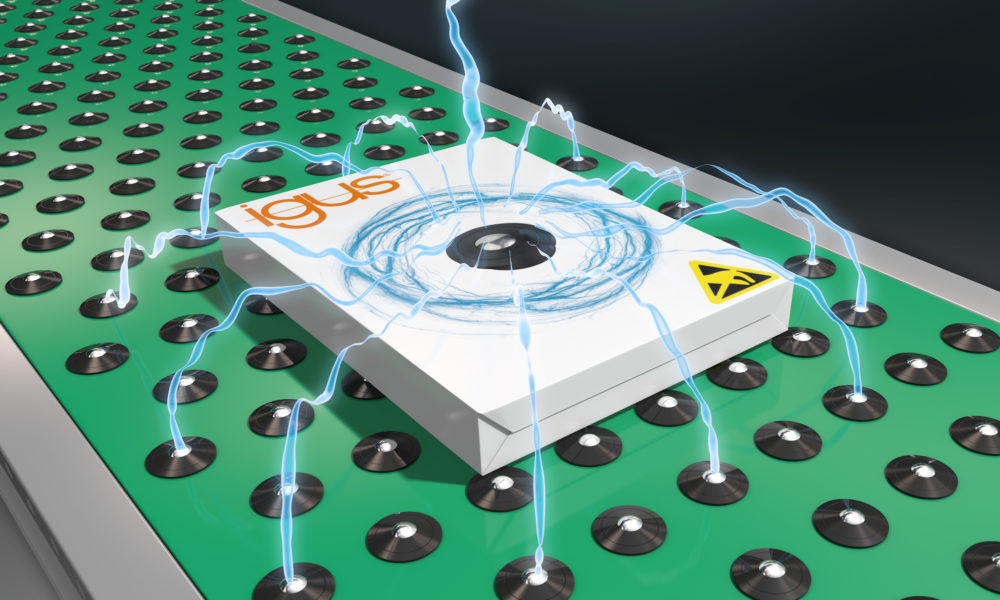

New xirodur F182 material from igus for ball transfer units

February 28, 2020 3:17 pm

Users rely on ball tables for transducers in roller conveyors and for the transport of sensitive goods. Here igus polymer ball transfer units are used because they can even move loads up to 500N smoothly and in all directions without any lubricant. To protect both conveyed goods and people from uncontrolled static electricity discharge, igus has now developed the tribo-polymer xirodur F182 for its ball transfer units. The new material is extremely durable and has proved its electrostatic conductivity in tests.

In cold weather and dry air, it happens generally: when touching an object or shaking a person’s hand, suddenly a slight electric shock passes through the body. Protection from electric shock can only be provided by textiles that do not become charged. The situation is similar in industry. If you work in production, you wouldn’t want to get a shock whenever you touch a box or a product. Here, electrostatically conductive materials are required. So, igus has now developed the xirodur F182 material for its xiros polymer ball transfer units. The ball transfer units are chiefly used in ball tables to move sensitive or heavy loads — up to 50 kg per unit, depending on size — in all directions. A smooth and lubrication-free transport is possible by the use of abrasion-resistant and durable tribo-polymers. Thanks to the special composition of the new xirodur F182 material, static charge can now be dissipated by the ball transfer unit. It is a significant advantage over metallic ball transfer units, which have an insulating effect by the use of lubricant. Such electrostatically dissipative components are required especially in the computer and semiconductor industries because a surge of electrostatic charge not dissipated by an insulating material can easily destroy the product.

Test proves conductivity

In the in-house 3,800-square-metre test laboratory, the electrostatic conductivity of the ball transfer units was examined. The ball transfer units made of the new material xirodur F182 were tested against ball transfer units made of the tried-and-tested xirodur B180. While xirodur B180 had a surface resistance of 1012 Ω in the laboratory and had an insulating effect, xirodur F182 had a surface resistance of less than 105 Ω and is therefore classified in the conductive category according to DIN EN 61340-5-1. As a result, when using the polymer ball transfer units, the user can be sure that puncture voltages are not discharged onto the transported goods or the employees.

For more information, visit:

www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.