Yokogawa selected as system integrator for OPA field trial

April 12, 2022 2:03 pm

Collaboration on ExxonMobil project to advance OPA system from test bed to real-world production process facility.

Yokogawa Electric Corporation has been selected by ExxonMobil as the system integrator for the first field trial of an Open Process Automation (OPA) system designed to operate an entire production facility. The field trial will take place at an ExxonMobil manufacturing facility located on the U.S. Gulf Coast, replacing the existing distributed control system (DCS) and PLC with a single, integrated system that meets the Open Process Automation Standard (O-PAS™). The project will incorporate enhanced control capabilities enabled through the implementation of OPA technologies and interfaces. “ExxonMobil is excited to have reached this important milestone with Yokogawa and progress the first field trial of an OPA system at an existing ExxonMobil manufacturing plant,” stated Ryan Smeltzer, OPA program manager for ExxonMobil Research and Engineering Company. “The project will take advantage of significant progress made testing OPA components and the O-PAS standards in close collaboration with Yokogawa. The OPA field trial is the next step in commercialising OPA and capturing additional value from our automation and control systems.

Most process industries are burdened with integrating multiple proprietary systems in almost every process plant and facility. These include manufacturing execution systems, DCSs, PLCs, and their respective human-machine interfaces and inputs/outputs (I/O). This can result in elevated capital costs on new projects and a high total cost of ownership, especially in the operation and maintenance of such systems. An OPA system is designed to remedy these challenges by supporting the integration of best-in-class components from different suppliers through configuration and application portability. This enables optimization of the total cost of automation systems. The field trial is a major milestone in Yokogawa’s continued support of ExxonMobil and OPA, and shifts OPA technology from concept to a viable alternative to traditional automation for process industries. The company has commenced work on the FrontEnd Engineering Design phase of the project. The OPA field trial system, which involves over 2000 I/O, is expected to be commissioned in 2023.

For the past two years, ExxonMobil and Yokogawa have been developing, testing, and improving OPA technologies through the joint operation of an OPA test bed located near ExxonMobil’s Houston, Texas campus. This collaborative work has developed and qualified many of the core OPA functions in preparation for the field trial. In addition to the field trial, test bed engineers at the Houston-area development office will continue to implement and refine OPA technologies in-line with the latest version of the O-PAS standard. Open Process Automation is a standards-based, open, secure, interoperable process control architecture being developed by the Open Group Open Process Automation™ Forum (OPAF), a consensus-based group of end users, suppliers, system integrators, standards organisations, and academia. Both ExxonMobil and Yokogawa Electric Corporation are members of OPAF.

Yokogawa to launch cloud-enabled version of CI Server

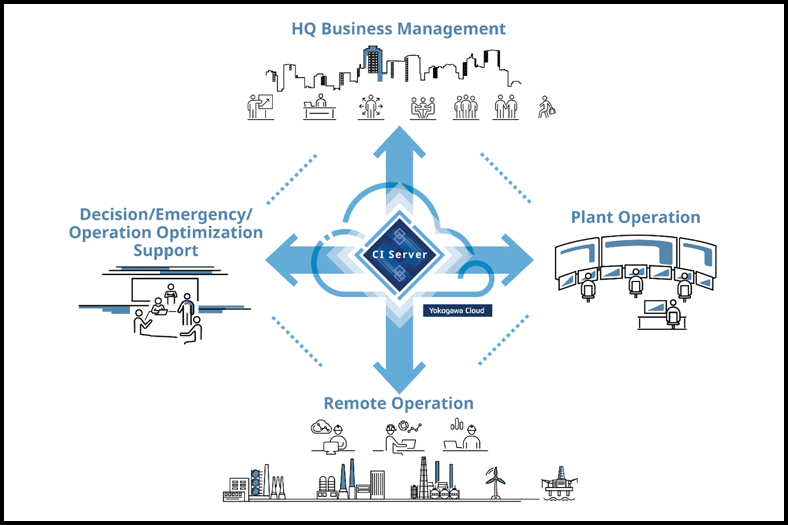

A product in the OpreX Control and Safety System Family – Delivery on Yokogawa Cloud enables safer and more efficient operation. Yokogawa Electric Corporation will release Collaborative Information Server (CI Server) R1.02 in March 2022. This new version of CI Server, a product in the OpreX™ Control and Safety System family, will have the ability to be delivered on Yokogawa Cloud, the company’s cloud platform.

Key Benefits

- Lower cost project implementation and swift project launch Running CI Server in a cloud environment enables a reduction in the number of PCs and other such hardware in plants. This eliminates the need for design and configuration work necessary for hardware setup, and speeds up project development. Furthermore, initial implementation costs are lower.

- Safe and efficient operation: With reduction in hardware, maintenance workload is reduced. And as server capacity can be scaled up for cloud based operations, it is possible with this version of CI Server to swiftly respond to changes in the operating environment. The combination of CI Server with Yokogawa Cloud can also reduce the need for cloud environment-related maintenance.

Yokogawa Cloud is an industrial transformation and IoT platform that accelerates the development and deployment of industrial cloud applications. It supports the ingestion, processing, and curation of data from various sources, provides industry-specific algorithms and models, and integrates across applications to support insightful decision-making and higher levels of automation.

For more information Open Process Automation: https://www.yokogawa.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.