Multi Axis CNC Robotics: Meeting the needs of SMEs

August 17, 2015 5:44 pm

We are targeting SMEs and smaller entrepreneurs to provide customised CNC machines according to their budget, area, and power requirements.

– Rajesh Kushwaha, Managing Director, Multi Axis CNC Robotics

A perfect startFounded in 2001 in a small workshop in Delhi, Multi Axis CNC Robotics is emerging as one of the significant players in the CNC machines manufacturing segment.

The company developed its prototype CNC milling in 2009. After making its first machine, Multi Axis CNC Robotics decided to run the same first at its own shop floor to understand breakdown, maintenance, service area etc. Later, the company contacted Maruti-Suzuki vendor for their job work on the same machine. There, the company ran the machine for one-and-a-half years successfully and earned Rs 28 lakh from job work! Since then, there is no looking back.

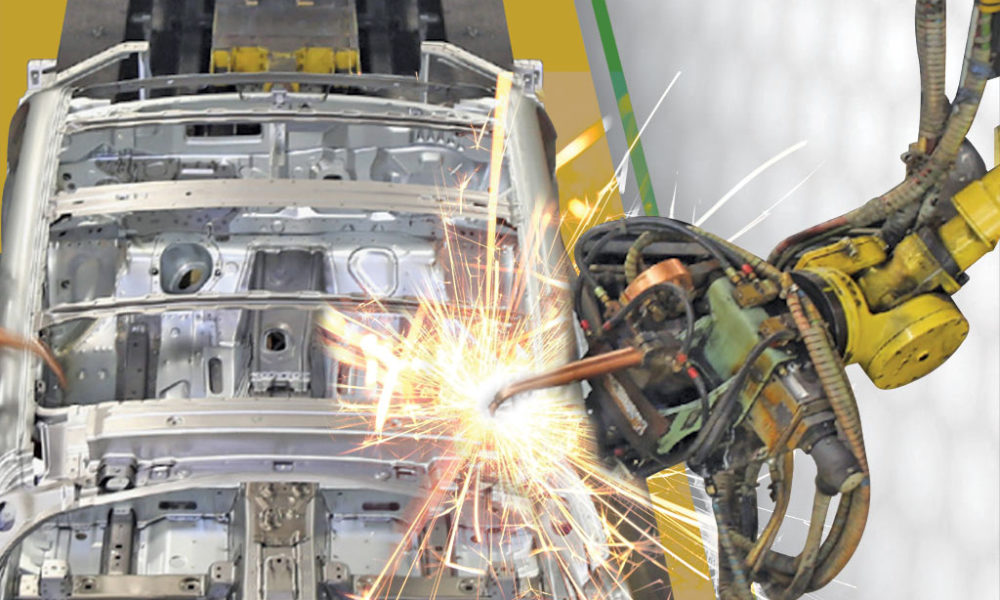

Today, Multi Axis CNC Robotics manufactures vertical machining centres, horizontal machining centres, CNC milling machines, engraving machines, wooden routers, stone routers etc. Its machines are widely used in dies and moulds like injection mould, press tools, pressure die casting, forging dies, metal patterns, auto components machining, shoe moulds, graphite electrode machining, wooden doors, wooden carving, stone carving, jewellery making, dental solutions etc.

Meeting the needs of SMEsCNC machines are most important nowadays in each and every tool room. They are fast replacing the conventional machines and producing high accuracy while saving time, power, money and manpower. Talking on the company’s achievements Rajesh Kushwaha, Managing Director, Multi Axis CNC Robotics, said, “Though we are catering to small and medium segments, recently we have developed bigger machines and entered in the market where others big players are selling their machines. As Prime Minister Narendra modi said SME sector is the backbone of our economy and it has to be strengthened, we are targeting SMEs and smaller entrepreneurs to provide customised CNC machines according to their budget, area, and power requirements. Even we are making CNC milling in single-phase power connection.”

Customising solutionsMulti Axis CNC Robotics offers high precision CNC milling and CNC engraving machines that further used in dies and mould manufacturing. Highlighting the advantages of the company’s CNC machines, Mr Kushwaha said, “Our each and every machine is customised as per customer demands. We customise machines as per customers’ application, shop floor size, power connection and their budget. We use spares parts from leading global manufactures. We are making our machines with Mitsubishi M70V controller for better performance in dies and mould application.”

Multi Axis CNC Robotics is also using Hiwin-Taiwan products for high accuracy motion.

Manufacturing capacityMulti Axis CNC Robotics produces 50 to 60 CNC machines a year. “We are growing faster as our machines are running successfully in the market since long without major breakdown,” Mr Kushwaha avers.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.